Flemish Eye Carbon Steel Sleeves

- (Sub Zero) for high performance in cold environments.

- Made in USA.

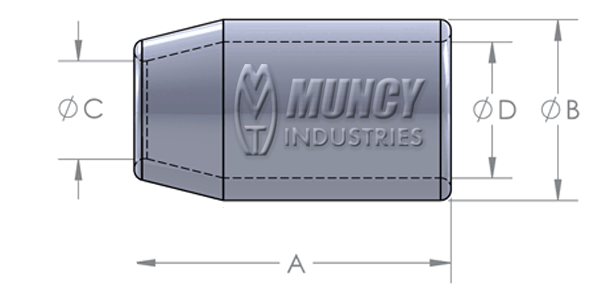

| Stock No. | Rope Size | Dimensions | Weight lbs. Each | ||||||

| Black Oxide | Zinc Plated | A | B | C | D | After Swage | |||

| Nominal | Max | ||||||||

| 45025040 | 45025060 | 1/4 | 1 | 21/32 | 11/32 | 15/32 | 0.50 | 0.57 | 0.04 |

| 45031340 | 45031360 | 5/16 | 1-1/2 | 29/32 | 7/16 | 19/32 | 0.73 | 0.75 | 0.14 |

| 45037540 | 45037560 | 3/8 | 1-1/2 | 29/32 | 15/32 | 21/32 | 0.73 | 0.75 | 0.12 |

| 45043840 | 45043860 | 7/16 | 2 | 1-7/32 | 9/16 | 27/32 | 0.98 | 1.01 | 0.32 |

| 45050040 | 45050060 | 1/2 | 2 | 1-7/32 | 5/8 | 29/32 | 0.98 | 1.01 | 0.28 |

| 45056340 | 45056360 | 9/16 | 2-3/4 | 1-15/32 | 11/16 | 1-1/32 | 1.20 | 1.24 | 0.63 |

| 45062540 | 45062560 | 5/8 | 2-3/4 | 1-15/32 | 3/4 | 1-3/32 | 1.20 | 1.24 | 0.56 |

| 45075040 | 45075060 | 3/4 | 3-3/16 | 1-23/32 | 7/8 | 1-9/32 | 1.41 | 1.46 | 0.88 |

| 45087540 | 45087560 | 7/8 | 3-7/16 | 2-1/32 | 1-1/32 | 1-17/32 | 1.63 | 1.68 | 1.38 |

| 45100040 | 45100060 | 1 | 4 | 2-9/32 | 1-7/32 | 1-3/4 | 1.88 | 1.93 | 1.90 |

| 45112540 | 45112560 | 1-1/8 | 4-1/2 | 2-1/2 | 1-7/32 | 1-15/16 | 2.08 | 2.13 | 2.60 |

| 45125040 | 45125060 | 1-1/4 | 5-1/8 | 2-25/32 | 1-7/16 | 2-5/32 | 2.27 | 2.32 | 3.40 |

| 45137540 | 45137560 | 1-3/8 | 5-11/16 | 3 | 1-9/16 | 2-11/32 | 2.46 | 2.52 | 4.30 |

| 45150040 | 45150060 | 1-1/2 | 6-3/16 | 3-9/32 | 1-23/32 | 2-5/8 | 2.65 | 2.71 | 5.00 |

| 45162540 | 45162560 | 1-5/8 | 7-9/32 | 3-23-32 | 1-7/8 | 2-7/8 | 3.04 | 3.10 | 8.30 |

| 45175040 | 45175060 | 1-3/4 | 7-1/4 | 3-27/32 | 2-1/16 | 3-1/8 | 3.04 | 3.10 | 8.40 |

| 45200040 | 45200060 | 2 | 8-17/32 | 4-3/8 | 2-11/32 | 3-5/8 | 3.50 | 3.56 | 11.30 |

| 45225040 | 45225060 | 2-1/4 | 9-11/16 | 5-1/32 | 2-1/2 | 4-1/32 | 4.06 | 4.12 | 19.20 |

| 45250040 | 45250060 | 2-1/2 | 10-17/32 | 5-1/2 | 2-15/16 | 4-1/2 | 4.44 | 4.50 | 23.20 |

| 45275040 | 45275060 | 2-3/4 | 11-7/8 | 5-3/4 | 3 | 4-23/32 | 4.64 | 4.70 | 28.00 |

| 45300040 | 45300060 | 3 | 12 | 6 | 3-1/4 | 5 | 4.89 | 4.96 | 29.40 |

| 45325040 | 45325060 | 3-1/4 | 13-1/8 | 6-1/2 | 3-7/8 | 5-7/16 | 5.31 | 5.37 | 36.00 |

| 45350040 | 45350060 | 3-1/2 | 14 | 7 | 3-29/32 | 5-7/8 | 5.70 | 5.77 | 46.40 |

| 45375040 | 45375060 | 3-3/4 | 15 | 7-1/2 | 4 | 6-11/32 | 6.17 | 6.23 | 50.00 |

| 45400040 | 45400060 | 4 | 16 | 8-1/8 | 4-3/8 | 6-27-32 | 6.62 | 6.69 | 69.00 |

*Can be customized upon request *All dimensions are in inches unless otherwise noted *Dimensions are subject to tolerance

CAUTION

Flemish Eye Carbon Steel Sleeves are recommended for use on 6x19 or 6x37 IPS or XIP, EIP, RRL, FC, or IWRC wire rope. Proper swaging practices are the sling manufacturer’s responsibility. Before using sleeves with other type lay, construction or grade of wire rope, it is recommended that the termination be tested to prove the adequacy of the assembly for its intended use. Proper swaging practices are the assembly manufacturer’s responsibility.