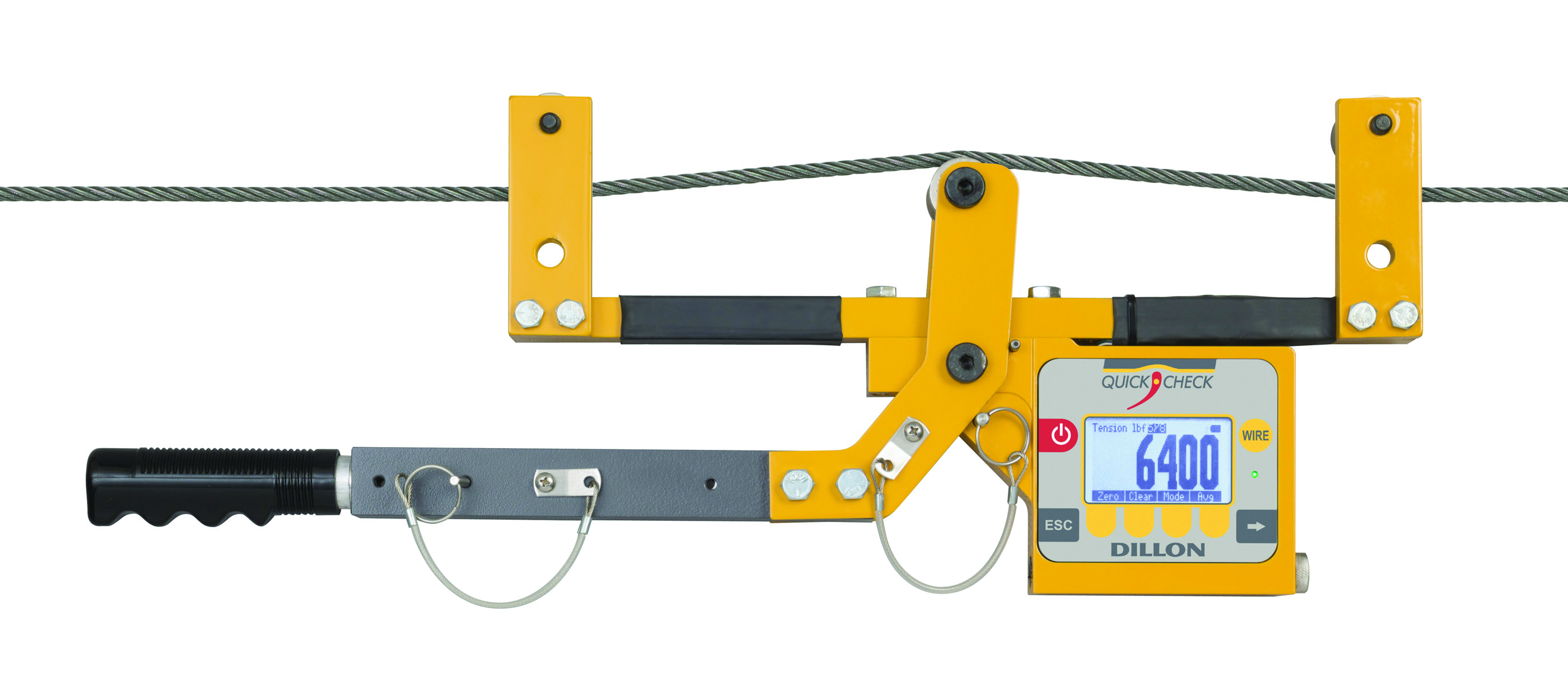

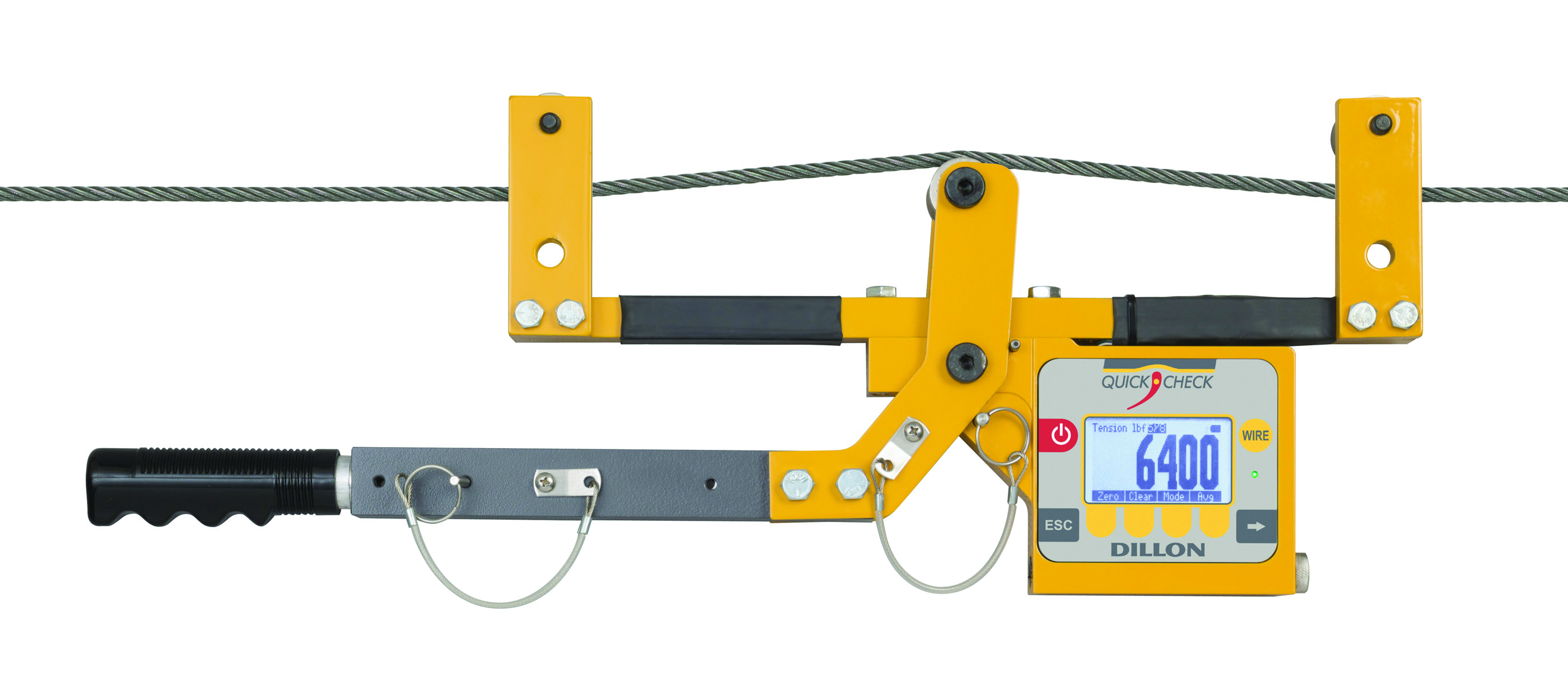

Dillon Quick-Check Tension Meter

| 2,000 x 2 lbf |

36289-0022 |

| 10,000 x 10 lbf |

36289-0014 |

| L |

ANY - 1/4” |

36309-0085 |

| P |

ANY - 1/2” |

36309-0044 |

| S |

1/4” - 3/4” |

36309-0010 |

| T |

1/2” - 1” |

36309-0101 |

Features:

- Sheaves with bearings eliminate friction and provide the best accuracy

- Accommodates a wide range of wire sizes and styles

- Telescoping handle engages meter quickly with minimal effort

- Highly visible yellow finish Easy-to-read display with full-text prompts

- Uses popular AA batteries and has long life between changes

- Easy to use soft-key interface

What size sheaves should be purchased?

It makes sense to take advantage of the range for the sheaves. Most customers can make do with one set of sheaves for the entire assortment of wires they tension by installing the sheave set that matches the largest diameter cable being used. If a customer checks tension in both 3/4" and 3/16" rope, then they should order two sheave sets, sheave code “L” & “S”. The operator must use the appropriate sheave set for the wire size and calibration stored. Changing sheave sets takes about two minutes with the included wrench.

| 3/16” |

1,000lbf |

Y |

Y |

Y |

|

Y |

|

| 1/4” |

2,000lbf |

Y |

Y |

Y |

Y |

Y |

|

| 5/16” |

3,000lbf |

Y |

|

Y |

|

Y |

|

| 3/8” |

3,500lbf |

Y |

Y |

Y |

Y |

Y |

|

| 7/16” |

4,000lbf |

Y |

|

Y |

|

|

|

| 1/2” |

5,000lbf |

Y |

Y |

Y |

|

Y |

Y |

| 9/16” |

6,000lbf |

Y |

Y |

Y |

|

|

|

| 5/8” |

7,000lbf |

Y |

Y |

Y |

Y |

|

Y |

| 3/4” |

8,000lbf |

|

Y |

Y |

Y |

|

|

| 7/8” |

9,000lbf |

|

Y |

Y |

|

|

|

| 1” |

10,000lbf |

|

Y |

Y |

|

|

|

*

or maximum capacity of Quick-Check/ whichever is lower.

| Sparrow |

2 AWG |

0.316 |

ACSR |

No |

1710 lbf |

| Raven |

1/0 |

0.398 |

ACSR |

No |

2628 lbf |

| Penguin |

4/0 |

0.563 |

ASCR |

No |

3636 lbf |

| Chickadee |

397.5 |

0.743 |

ACSR |

No |

3636 lbf |

| Petunia |

750 |

0.997 |

AAC |

No |

3636 lbf |

| 1/2" |

6 x 26 wire core |

5,000 lbf |

| 3/4" |

3 x 7 standard safety (unstretched) |

6,000 lbf |

| 3/4" |

3 x 7 pre-stretched safety |

8,000 lbf |

| 5 mm |

1 x 7 stainless steel |

1,000 lbf |

| 3/16" |

solid steel (pre-stressed concrete) |

7,000 lbf |

Specifications

- Tension capacities:

2000 lb/10 kN/1000 kg.

8000 lb/35 kN/3500 kg.

- Wire sizes: 3/16 inch through 3/4 inch.

- Accuracy: ±3% instrument capacity (calibrated to specific wire size).

- Number of calibrations: Up to 15 can be stored independently.

- Operating range: -4°F to 140°F (-20°C to 60°C)

- Loading error: Cable elongation of only 0.08 inch (2mm)

- Display: Dot-graphic LCD display supports full text and 1 inch high digits.

- Environment protection: Suitable for continued outdoor use.

- Tension units of measure: pound-force, kilogram force, Newtons.

- Resolution: configurable low/med/high.

- Recalibration: At user discretion. Commonly 24 months but should be more frequently with heavy use. Factory recalibrations conducted typically in 2-4 days. On-site recalibration may be possible through your Dillon distributor.

- Size: 10 x 23 x 3 inch (25 x 59 x 8 cm).

- Weight: Approx 11 lb (5 kg)