Upson-Walton™ Closed Swage Sockets

Muncy manufactures the Upson-Walton Swage Socket product line. Our forgings use special steel with mechanical and physical properties that enhance swaging, durability, and strength. Upson-Walton closed swage sockets are sometimes used by themselves for specific pins, or in conjunction with our open swage sockets.

Upson-Walton Swage Sockets are Made in USA

Muncy manufactures its Upson-Walton swage sockets from material and forgings that we make in the USA. Muncy machines and performs its secondary processes in the United States. When you receive a swage socket with an “Upson-Walton” or “UW” on the forging, you can know with confidence it was Made In USA.

Upson-Walton Sockets are easy to swage onto Wire Rope

Many of our customers tell us they like how our swage sockets swage onto wire rope. Our heat treat process is designed with the swaging process in mind, as the socket is subjected to extreme pressure between dies during swaging.

EFFICIENT, QUICK and POSITIVE

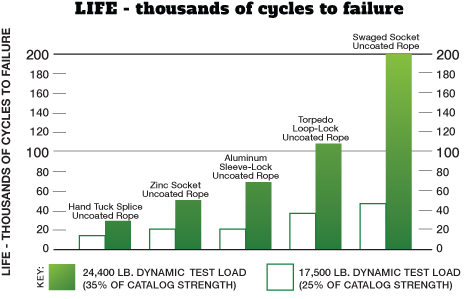

Why pour zinc or epoxy when swaging is sure? Swage sockets have as much as five times longer life than spelter sockets.

Tests prove swage sockets have the best fatigue life

An extensive research study by one of the nation’s steel companies clearly established the fatigue life superiority of swaged sockets over other commonly used types of boom pendants. The tests included applied dynamic longitudinal load to the rope. They also simulated stresses which occur in pendant service. The graph at the right shows the results of these tests.

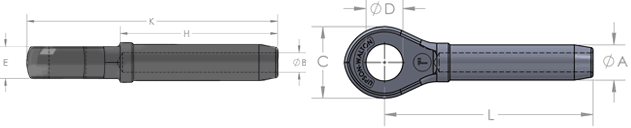

| Stock No. | Rope Size(inch) | Dimensions | Weight lbs. Each | UltimateLoad(tons) | After Swage | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C* | D | E* | H | K | L | Nominal | Max | ||||

| 41025002 | 1/4" | 0.50 | 0.27 | 1-7/16 | 0.75 | 1/2 | 2-1/8 | 4-3/8 | 3-1/2 | 0.35 | 3.74 | 0.438 | 0.460 |

| 41031302 | 5/16" | 0.77 | 0.34 | 1-11/16 | 0.88 | 11/16 | 3-3/16 | 5-1/2 | 4-1/2 | 0.77 | 5.8 | 0.688 | 0.710 |

| 41037502 | 3/8" | 0.77 | 0.41 | 1-11/16 | 0.88 | 11/16 | 3-3/16 | 5-1/2 | 4-1/2 | 0.73 | 8.3 | 0.688 | 0.710 |

| 41043802 | 7/16" | 0.98 | 0.48 | 2 | 1.06 | 7/8 | 4-1/4 | 6-15/16 | 5-3/4 | 1.47 | 11.2 | 0.875 | 0.910 |

| 41050002 | 1/2" | 0.98 | 0.55 | 2 | 1.06 | 7/8 | 4-1/4 | 6-15/16 | 5-3/4 | 1.38 | 14.6 | 0.875 | 0.910 |

| 41056302 | 9/16" | 1.26 | 0.61 | 2-1/2 | 1.25 | 1-1/8 | 5-5/16 | 8-3/4 | 7-1/4 | 2.90 | 18.5 | 1.125 | 1.160 |

| 41062502 | 5/8" | 1.26 | 0.67 | 2-1/2 | 1.25 | 1-1/8 | 5-5/16 | 8-3/4 | 7-1/4 | 2.80 | 22.7 | 1.125 | 1.160 |

| 41075002 | 3/4" | 1.55 | 0.80 | 3 | 1.44 | 1-5/16 | 6-3/8 | 10-3/8 | 8-5/8 | 5.16 | 43.5 | 1.375 | 1.420 |

| 41087502 | 7/8" | 1.70 | 0.94 | 3-1/2 | 1.69 | 1-1/2 | 7-7/16 | 12-1/8 | 10-1/8 | 7.40 | 51.5 | 1.500 | 1.550 |

| 41100002 | 1" | 1.98 | 1.06 | 4 | 2.06 | 1-3/4 | 8-1/2 | 13-3/4 | 11-1/2 | 11.20 | 71.4 | 1.750 | 1.800 |

| 41112502 | 1-1/8" | 2.25 | 1.19 | 4-1/2 | 2.31 | 2 | 9-9/16 | 15-1/4 | 12-3/4 | 16.00 | 83.3 | 2.000 | 2.050 |

| 41125002 | 1-1/4" | 2.53 | 1.33 | 5 | 2.56 | 2-1/4 | 10-5/8 | 17-1/4 | 14-3/8 | 22.70 | 109 | 2.250 | 2.300 |

| 41137502 | 1-3/8" | 2.80 | 1.45 | 5-1/4 | 2.56 | 2-1/4 | 11-11/16 | 18-7/8 | 15-3/4 | 29.00 | 106 | 2.500 | 2.560 |

| 41150002 | 1-1/2" | 3.08 | 1.58 | 5-1/2 | 2.81 | 2-1/2 | 12-3/4 | 20-3/8 | 17 | 37.50 | 125 | 2.750 | 2.810 |

| 41175002 | 1-3/4" | 3.39 | 1.86 | 6-3/4 | 3.56 | 3 | 14-7/8 | 24 | 20 | 55.70 | 169 | 3.000 | 3.060 |

| 41187502 | 1-7/8" | 3.94 | 2.00 | 7-3/4 | 3.80 | 3-1/4 | 17 | 27-5/8 | 23 | 92.00 | 192 | 3.500 | 3.560 |

| 41200002 | 2" | 3.94 | 2.11 | 7-3/4 | 3.80 | 3-1/4 | 17 | 27-5/8 | 23 | 90.00 | 217 | 3.500 | 3.560 |

| 41225002 | 2-1/4" | 4.45 | 2.36 | 8-7/8 | 4.31 | 4 | 19-1/8 | 29-3/4 | 24-7/8 | 125.00 | 272 | 4.000 | 4.045 |

| 41237502 | 2-3/8" | 4.93 | 2.55 | 8-7/8 | 4.31 | 4 | 19-5/8 | 31-1/8 | 24-7/8 | 132.00 | 302 | 4.375 | 4.420 |

| 41250002 | 2-1/2" | 4.93 | 2.66 | 8-7/8 | 4.31 | 4 | 19-5/8 | 31-1/8 | 26-1/4 | 142.00 | 332 | 4.375 | 4.420 |

| 41275002 | 2-3/4" | 5.43 | 2.92 | 9-7/8 | 5.06 | 5-1/4 | 21-1/8 | 35-3/8 | 29-9/16 | 227 | 397 | 4.710 | 4.770 |

| 41300002 | 3" | 5.96 | 3.17 | 9-7/8 | 5.31 | 5-1/4 | 23-3/4 | 37-7/8 | 32-3/16 | 255 | 468 | 5.250 | 5.310 |

* Subject to Forging Tolerances

CAUTION

Closed Swage Sockets are recommended for use on 6x19 and 6x37 IPS or XIP (EIP), XXIP (EEIP), RRL, or IWRC wire ropes. They are also approved for use on galvanized bridge rope. Before using swage sockets with other type lay, construction or grade of wire rope, it is recommended that the termination be tested to prove the adequacy of the assembly in the intended application. Proper swaging practices are the assembly manufacturer’s responsibility.

- Stainless Steel Closed Swage Sockets

Other Materials Available

- Open Swage Sockets

- Stainless Steel Closed Swage Sockets

- Boom Pendant Open Swage Sockets

- Boom Pendant Closed Swage Sockets

Similar Products

- Open Rope Spelter Sockets

- Closed Rope Spelter Sockets

- Stainless Steel Open Rope Spelter Sockets

- Flat Rope Spelter Sockets

- Open Strand Spelter Sockets

- Closed Strand Spelter Sockets

- Type 6 Anchor Sockets

- Type 7 Anchor Sockets

- Type 8 Anchor Sockets

- Open Boom Pendant Sockets

- Closed Boom Pendant Sockets

- Open Bridge Bowl Sockets

- Closed Bridge Bowl Sockets

- Vibration Dampening Fittings