Aluminum Fiber Rope Sleeves | Muncy Industries

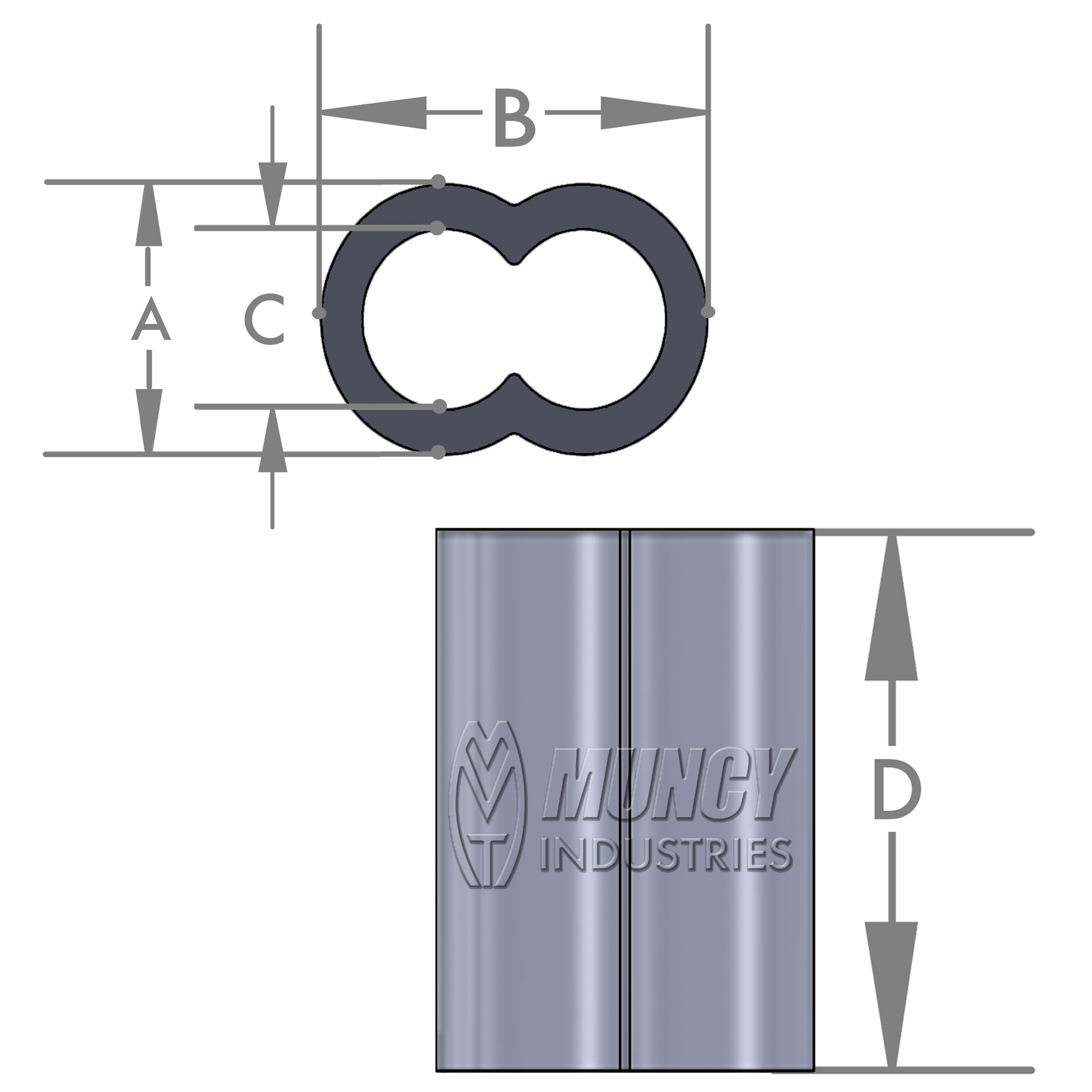

| Stock No. |

Rope Dia. |

Dimensions | After Swage Dia | Weight (lbs. per 1,000) |

||||

| A | B | C | D | Nominal | Max | |||

| FR-4 | 1/8” | 1/4 | 3/8 | 5/32 | 1/2 | 0.250 | 0.260 | 1.8 |

| FR-6 | 3/16” | 3/8 | 9/16 | 1/4 | 11/16 | 0.375 | 0.385 | 5.4 |

| FR-8 | 1/4" | 7/16 | 21/32 | 21/64 | 1 | 0.438 | 0.448 | 9.2 |

| FR-14 | 7/16" | 55/64 | 1-23/64 | 17/32 | 1-1/4 | 0.855 | 0.885 | 69.8 |

CAUTION

Proper swaging practices are the assembly manufacturers responsibility. The assembly must be properly swaged to attain expected strength of the return eye splice of the wire rope. Testing is recommended to prove the adequacy of the assembly in the intended application.

- Casing Thimbles

- Slip-Through Thimbles

- Carbon Steel Thimbles

Alumium Swage Sleeves are Used With:

- Copper Swage Sleeves