Upson-Walton™ Stainless Steel

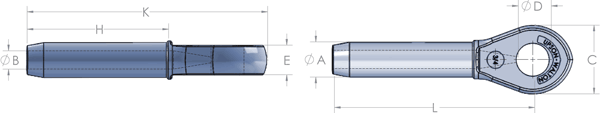

Closed Swage Sockets

| Stock No. | Rope Size | Dimensions | After Swage Min - Max | |||||||

| A | B | C | D | E | H | K | L | |||

| 41025050 | 1/4 | 0.495 | 0.272 | 1-7/16 | 0.750 | 1/2 | 2-1/8 | 4-3/8 | 3-1/2 | 0.428 - 0.460 |

| 41031350 | 5/16 | 0.770 | 0.339 | 1-11/16 | 0.875 | 11/16 | 3-3/16 | 5-1/2 | 4-1/2 | 0.678 - 0.710 |

| 41037550 | 3/8 | 0.770 | 0.406 | 1-11/16 | 0.875 | 11/16 | 3-3/16 | 5-1/2 | 4-1/2 | 0.678 - 0.710 |

| 41043850 | 7/16 | 0.982 | 0.484 | 2 | 1.063 | 7/8 | 4-1/4 | 6-15/16 | 5-3/4 | 0.865 - 0.910 |

| 41050050 | 1/2 | 0.982 | 0.547 | 2 | 1.063 | 7/8 | 4-1/4 | 6-15/16 | 5-3/4 | 0.865 - 0.910 |

| 41056350 | 9/16 | 1.257 | 0.609 | 2-1/2 | 1.250 | 1-1/8 | 5-5/16 | 8-3/4 | 7-1/4 | 1.115 - 1.160 |

| 41062550 | 5/8 | 1.257 | 0.672 | 2-1/2 | 1.250 | 1-1/8 | 5-5/16 | 8-3/4 | 7-1/4 | 1.115 - 1.160 |

| 41075050 | 3/4 | 1.545 | 0.796 | 3 | 1.438 | 1-5/16 | 6-3/8 | 10-3/8 | 8-5/8 | 1.365 - 1.420 |

| 41087550 | 7/8 | 1.700 | 0.938 | 3-1/2 | 1.688 | 1-1/2 | 7-7/16 | 12-1/8 | 10-1/8 | 1.490 - 1.550 |

| 41100050 | 1-0/0 | 1.975 | 1.062 | 4 | 2.063 | 1-3/4 | 8-1/2 | 13-3/4 | 11-1/2 | 1.740 - 1.800 |

| 41112550 | 1-1/8 | 2.245 | 1.188 | 4-1/2 | 2.313 | 2 | 9-9/16 | 15-1/4 | 12-3/4 | 1.990 - 2.050 |

| 41125050 | 1-1/4 | 2.525 | 1.328 | 5 | 2.563 | 2-1/4 | 10-5/8 | 17-1/4 | 14-3/8 | 2.240 - 2.300 |

CAUTION

Swage Sockets are recommended for use on 6 x 19 or 6 x 37 Stainless Steel wire rope. Stainless Steel sockets are also approved for use on IPS or XIP (EIP), XXIP (EEIP), RRL, or IWRC wire ropes. Before using swage sockets with other type lay, construction or grade of wire rope, it is recommended that the termination be proofloaded to prove the adequacy of the assembly.

- Closed Swage Sockets

Other Materials Available

- Open Swage Sockets

- Stainless Steel Open Swage Sockets

- Boom Pendant Open Swage Sockets

- Boom Pendant Closed Swage Sockets

Similar Products

- Open Rope Spelter Sockets

- Closed Rope Spelter Sockets

- Stainless Steel Open Rope Spelter Sockets

- Flat Rope Spelter Sockets

- Open Strand Spelter Sockets

- Closed Strand Spelter Sockets

- Type 6 Anchor Sockets

- Type 7 Anchor Sockets

- Type 8 Anchor Sockets

- Open Boom Pendant Sockets

- Closed Boom Pendant Sockets

- Open Bridge Bowl Sockets

- Closed Bridge Bowl Sockets

- Vibration Dampening Fittings